Reduce friction, maximize efficiency!

What is the advantage? By reducing friction between parts, you can:

- increase the lifespan of equipment by minimizing wear,

- facilitate the tightening of screws and bolts,

- reduce efforts to handle equipment,

- reduce energy losses,

- reduce noise.

How it works ? Our ranges of high performance slip varnishes and lubricating coatings adapt to all your constraints to reduce friction.

Results ? Parts that work longer, while requiring less maintenance.

Contact us today to learn more: Contactez-nous – APS Coatinhttps://www.aps-coatings.com/en/contact-us/

That's it, it's D-Day for the Paris 2024 Olympic Games!

At APS, we cultivate the values of sport, passion and unity.

We support athletes and para-athletes from all countries who will surpass themselves to come away with a medal! They are a source of inspiration and invite us to always push our limits and strive for excellence in everything we do.

Together, let’s celebrate this global event!

APS at the service of patients and medical staff

Our biocompatible coatings produced by thermal spraying or spraying guarantee anti-adhesion, resistance to sterilization products and provide essential antibacterial protection in sensitive medical environments.

Whether for your medical instruments, trays, centrifuge baskets or diagnostic needles, APS supports you for equipment that is easier to identify and use without risk of contamination.

Learn more about our solutions: https://www.aps-coatings.com/en/marche/coatings-for-the-healthcare-sector/

NMP-free formulations are progressing

We are moving forward with formulations without NMP (N-Methyl-2-Pyrrolidone)!

At APS, we are always looking for more responsible coatings that meet REACH regulations.

Samuel is responsible for formulating, and Kendy, one of our experienced applicators, is responsible for testing the formulations

Thanks to these tests, we seek to offer you the best for your parts.

Because beyond the surface, it’s your performance that we formulate.

Discover our Anti-Friction Coating Solutions

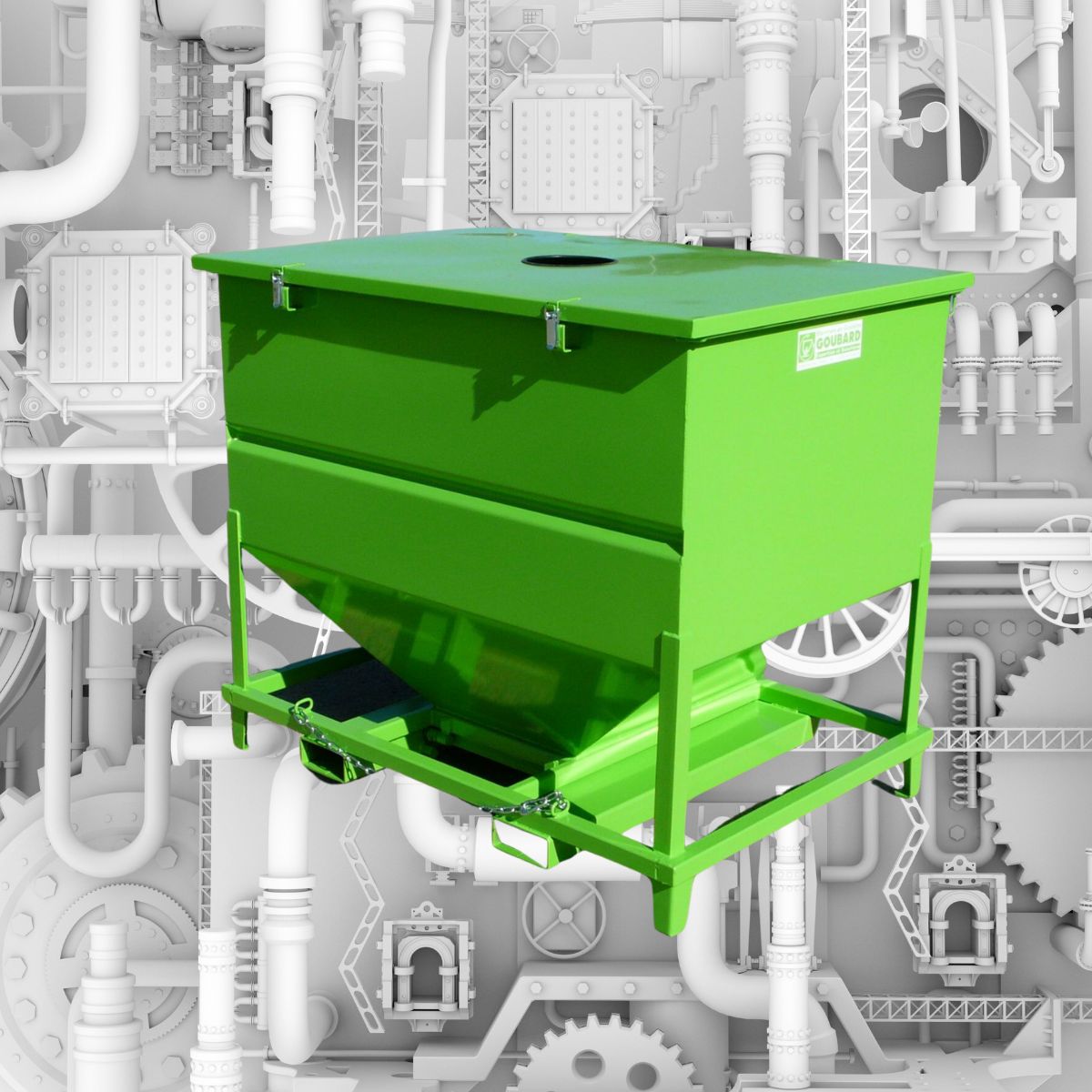

Optimize your hoppers!

At APS, we have the solution to improve the efficiency of your hoppers: anti-friction coatings!

Say goodbye to blockages and premature wear. Our coatings are designed to withstand the most demanding environments. Boost your productivity!

Don’t miss our next webinar on anti-friction coatings for top-notch hoppers!

To register (in French): https://events.teams.microsoft.com/event/7e52ca17-520e-4bb1-9785-4bddadc79684@bb18a701-c4bf-4a65-bd21-bd7d66ba109c