APS, the only parylene applicator in France

Parylene, what is it?

- A highly conformable coating:

- with excellent electrical insulation properties,

- chemically inert,

- hydrophobic with a low coefficient of friction,

- impermeable to gas and water,

- biocompatible.

It reliably encapsulates any 3D part in the most demanding technological fields, including medical, electronics, space and aeronautics, and micro and nanotechnology.

Do not hesitate to contact us to protect your printed circuits or other high-tech parts.

AERO THERMAL SPRAY COATING

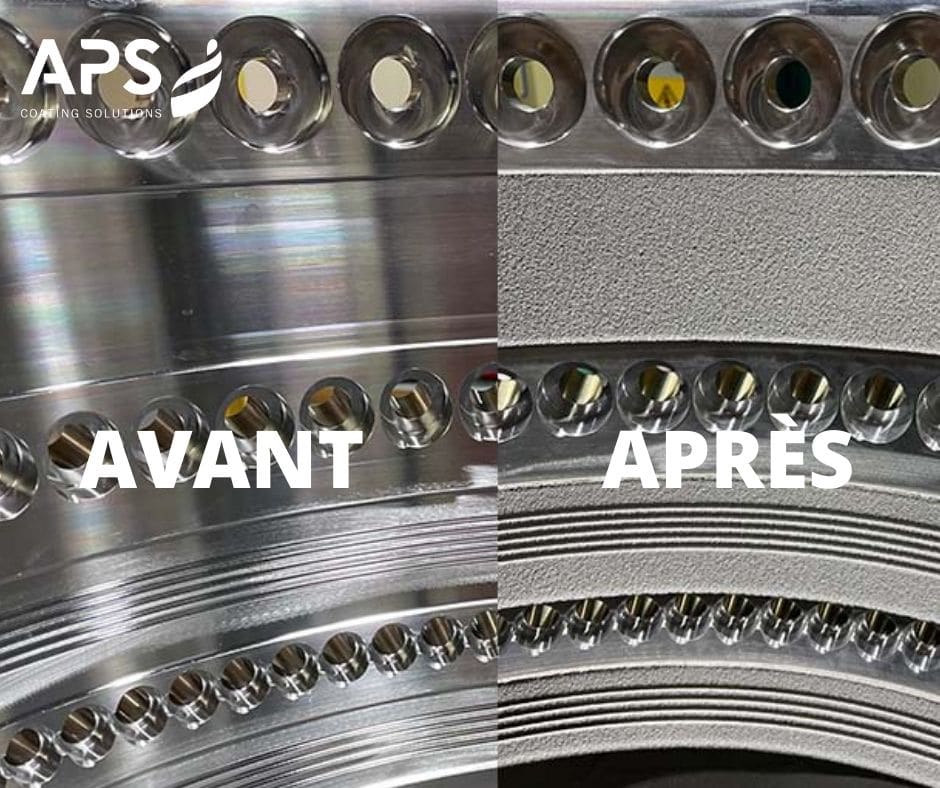

At APS, we apply the most complex coatings precisely to the areas defined by customer specifications.

Appreciate the quality of this abradable coating perfectly applied to this part.

It is the result of more than 50 years of know-how in aeronautical and high-tech parts.

Cothal™, a special coating for optics

Discover Cothal™, an APS Coatings formulation suitable for optical or photonic applications.

To learn more about this coating and our know-how, click here.

Beyond the surface, it is your performance that we are looking for.

Damien Pomarède - Optimizing the application of material thanks to light

Doctor in photonics and engineer in materials sciences, Damien Pomarède has been interested in coatings and the interaction between light and matter for a long time.

After an end-of-study internship at Airbus where he worked on smart coatings, he plunged into the development of glass-ceramics for laser applications as part of his thesis at the XLIM Research Institute. A brief transition at Capgemini and two years in charge of R&D projects on laser stripping processes at Silltec enabled him to perfect his skills in project coordination and his knowledge of laser processes in an industrial environment.

Now R&D project manager at APS Coating Solutions for nearly a year, he is in charge of the Laserblast project and answers our questions:

Why did you choose APS?

APS is in a dynamic of modernization with a strong desire to innovate which attracted me. For me, it is the ideal company to apply my knowledge of laser processes and materials, as well as my ability to lead innovation projects on very technical projects. In addition, APS is both a formulator and applicator of coatings, which makes it possible to work across the entire value chain and creates the ideal conditions for innovation.

What is the Laserblast project?

The parts treated by APS all follow a surface preparation step and an application step with areas to be coated and others to be spared.

The Laserblast project has two objectives:

1/ Carry out the preparation of the surface of the parts by laser in order to eliminate pollutants (greases, oils, oxides, dust, etc.). This makes it possible to obtain an ideal surface condition and roughness to maximize the adhesion and performance of the coatings.. Sort of a two-in-one surface preparation operation.

2/ Strip the coating on certain areas of the part in order to save money without resorting to masking these areas.

What are the expected benefits of this project?

Surface preparation and masking/unmasking on sometimes very complex and sensitive parts are time-consuming steps, sources of musculoskeletal disorders (MSDs) and using a lot of consumables.

This project will make it much easier to approach the processing of these complex parts. It will also ensure better repeatability of operations and increased accuracy.

Regarding operators, it will reduce exposure to dust and solvents during surface preparation and reduce the risk of MSDs related to repetitive gestures.

From an environmental point of view, the implementation of laser processes will eliminate the use and reprocessing of consumables such as degreasing solvents and sandblasting abrasives.

What is your work on this project?

My job is to follow schedules and budgets, conduct studies to quantify the impact and gains in texturing or stripping, supervise the production of machine prototypes and keep in touch with equipment manufacturers. Laser tests are carried out by an external partner and we characterize the surfaces obtained internally by measurements of surface energy, roughness, hardness, observations of metallographic structure, as well as measurements of adhesion and resistance to aging. coatings applied. Eventually, these measurements will be made by independent laboratories to provide the necessary technical guarantees to our customers.

What do you like about your role today?

I like the laser stripping process for its potential and versatility. It can, depending on the needs, be extremely abrasive when you want to texture a surface, or conversely be soft and selective when you have to remove a coating on a substrate without altering it. The results can be extremely impressive, with an awesome accuracy and repeatability.

And being able to work directly with coatings formulators opens up possibilities for innovation that I would never have found anywhere other than at APS.

From single parts to medium series, the Laserblast project is full of promises: superior coating quality, the processing of more sensitive and complex parts, the improvement of the CSR and HSE impacts of our activity and the development of innovative solutions, in line with the challenges of industry 4.0.

Maintenance part aerospace

These parts are tools used in aerospace maintenance and are coated with Nuflon WV, a special non-stick coating developed by APS Coatings.

Our coating makes it easy and quick to clean these parts while protecting them against corrosion.