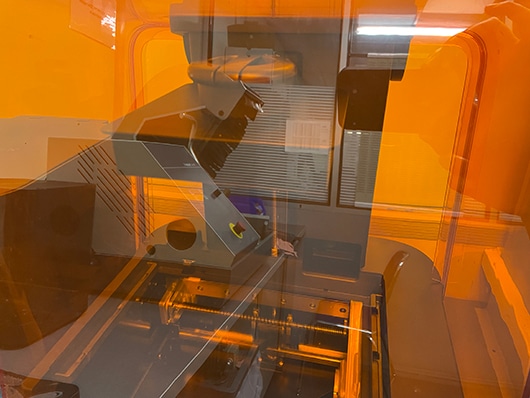

APS prototypes 3D printing tools

To optimize the application of all types of coating and process parts even faster, APS uses its 3D printer to create tooling prototypes.

“3D printing allows us to test our ideas much faster. Thus, this tool allows us to ensure precise masking areas, to streamline production flow and above all to process many more parts in a row!” comments Philippe Spilers, Innovation Director of APS Coatings.

The unmatched precision of those tools produced in record time thus makes it possible to significantly speed up order processing while maintaining very high quality production.

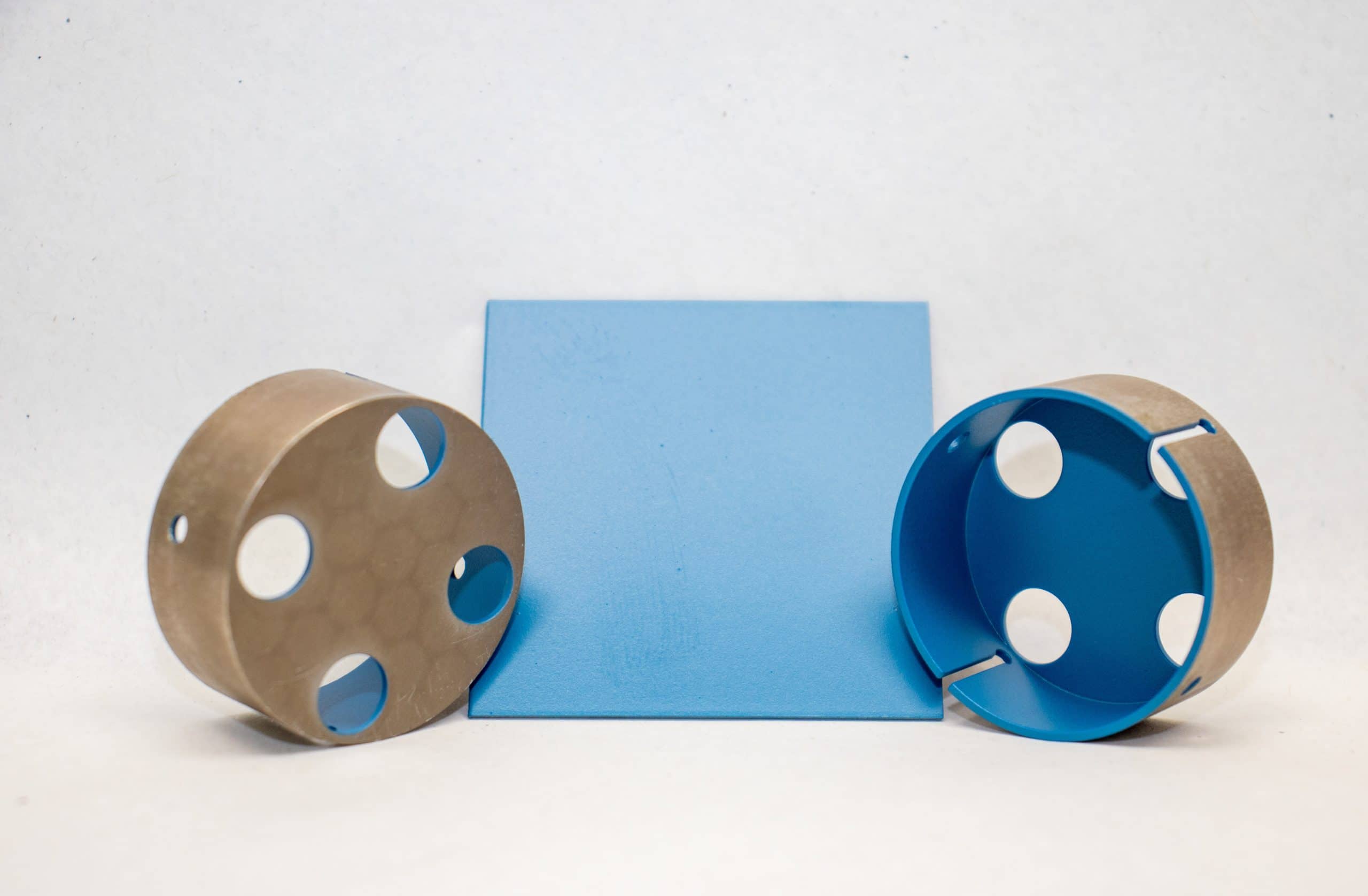

Surface preparation at APS

NUFLON TGBBT®, is a blue anti-stick coating.

Get a feel of our know-how, which allows us to make this coating stick to a metal substrate.

The part will be sent to the customer, with its test plate, to confirm the effectiveness of the adhesion of the coating.

We carry out these tests in order to meet quality requirements, particularly in the Aeronautics, Space and Defence industries.

Greener Nuflon Coatings

Innovation at APS also means providing our customers with more environmentally friendly high-performance coatings.

The range of NUFLON™ UH composite coatings has been developed by APS without chromic acid, without solvent, without POP (Persistent Organic Pollutants).

These hexagonal head screws in NUFLON™ UHA will have to meet severe constraints:

- Non-stick at high temperature (up to 400°C depending on conditions)

- Anti-friction under heavy loads and high temperatures

- REACH compliant

With APS, spared areas are super precise.

With APS, spared areas are super precise. Appreciate the know-how of our operators on this copper part coated with RILSAN® to allow its electrical insulation.

Many techniques are used to deposit the coating only on the areas you need. Here our part is isolated everywhere except at the level of the thread.

That’s not all, we are also working on new technologies for sparing areas via our Laser blast project!

Find out more about our innovation projects.

To be continued …

A water-based lubricating coating

APS is always on the lookout for high-performance coatings that reduce the impact on the environment.

Thus, we are qualified by several contractors for the application of Surf-Kote LOB-1800-G, a water-based lubricating coating.

After curing, this coating has lubricating properties at temperatures ranging from 370-760°C.

It is especially recommended for applications where other dry film lubricants containing molybdenum disulfide and/or Teflon are not acceptable.

Do not hesitate to contact us for more information!