Maintenance - Repair Operations

Repair techniques to extend the life of your parts

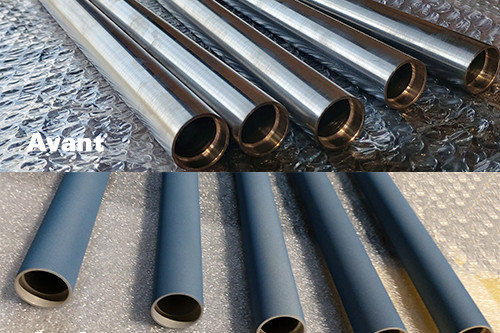

The repair of worn, deformed or out-of-tolerance parts is a major challenge in many industrial sectors, where the durability and precision of components are essential. There are several techniques widely applied in the fields of aeronautics, automotive, energy and industrial manufacturing to restore expensive and complex parts while optimizing equipment performance and reliability.

Our strengths:

APS Group companies offer some of the most effective techniques for restoring parts such as hard chrome plating, thermal spray metallization and grinding:

- Hard chrome plating makes it possible to produce extra thicknesses which will then be ground to size. These coatings provide excellent resistance to wear and corrosion, thus extending the life of critical parts.

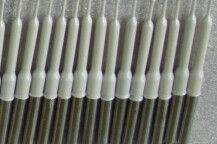

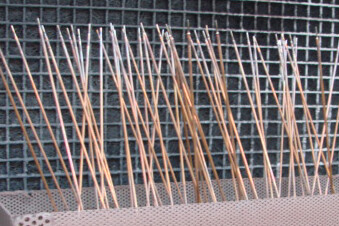

- HVOF or HP_HVOF spray allows layers of tungsten carbide to be deposited on parts exposed to oxidation or on joint or braid surfaces.

- Plasma spray offers the possibility of depositing layers of carbide, nickel or ceramics to reload rings and wear surfaces and to improve the thermal barriers of the parts.

- Flame spray or shooping makes it possible to apply layers of 13% chrome, molybdenum, zinc or bronze from a few tenths to several millimeters thick. The operators of the Lorilleux company also master the flame projection of polymer coatings such as Rilsan® Polyamide 11.

- Buffer electrolysis allows the localized deposition of copper, nickel and zinc-nickel for refilling impacts, scratches or parts with contact corrosion problems.

- Grinding makes it possible to precisely adjust the dimensions of the parts after their resurfacing, ensuring perfect compliance with the required tolerances.

To machine parts that are too bulky, difficult to transport or limit operating losses, our teams can intervene directly on your site. For more information on our on-site interventions, see our page.

Where do we operate?

All industries: Axes | Joint surfaces | Braid Stitches | Bearings | Crankshafts | Ball joints | Servomotors | Spherical Valves | Journals | Buildings | Pliers | Engine barrels | Shafts | Rings | Bearing seats | Coupling parts | Gears | Gables | Cylinders | Guides | Hubs | Brake drum | Reduction housings…

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Repairing

Anti-abrasion

Wear resistance

Atmospheric anticorrosion

Friction

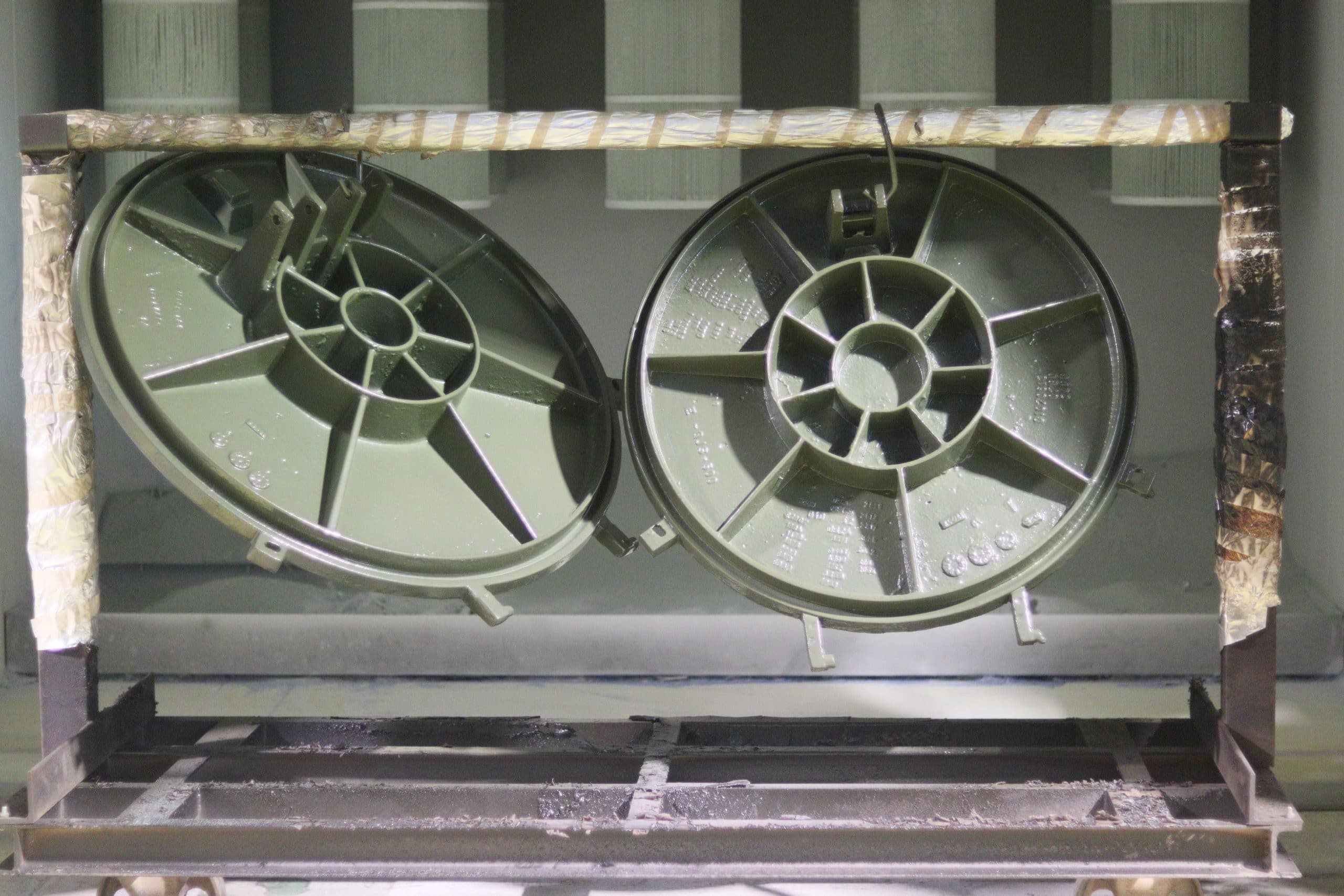

Coatings for the Automotive / Railway sector

New coatings to support an evolving industry

The transportation industry faces many challenges. APS helps you improve fuel efficiencywhile providing an exceptional driving experience by reducing noise and friction with non-stick coatings. Likewise, we support the transition to electric or hybrid vehicles with coatings implementing insulation or electrical conductivity properties. Finally, we support maintenance workshops in order to repair wearing parts of rolling stock or vehicles thanks to our spray metallization interventions on site or in our workshops.

Our strengths:

- Our tier-1 referencing with demanding customers and our industry certifications allow us to be part of programs such as Formula 1

- A zinc flake dip-spin process for the anti-corrosion treatment of large volumes of parts with reception mats allowing good separation of each part

- Many solutions offering electrical properties in paint spray or thermal spray

- Refilling of wearing parts for maintenance workshops

Where do we operate?

Automotive: Springs | Bolts | Wheel balancing weight | Fixings | Body Shafts | Rings | Bearings | Pumps | Coupling parts | Transmissions | Blades | Filters | Sieve | Fuel lines and fluid flow (braking, clutch system, cooling) | Seals | Exhaust systems | Electronic control unit | Sliding doors | Lithium-ion batteries | Connectors | Wiring | Seat rails…

Railway: Diesel engine parts (pistons, valves, seals, connecting rods, connectors, crankshafts, etc.) | Turbocharger Parts | Traction Motor Parts | Wiring | Compressor Parts | Nickel-cadmium and Lead batteries | Bogie parts (axles, bearings and cartridges, axle boxes, levers, connecting rods, wear plates, bearings, suspension, etc.) | Brake components (brake wishbones, brake linkage components, brake cylinders, distributors, brake shoes etc.) | Shock and traction devices | Tensioners and towing hooks| Interior equipment of passenger cars | electrical connection bars…

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Repairing

Anti-abrasion

Noise reduction

Fire resistance

Wear resistance

Atmospheric anticorrosion

Repairing

Friction

Electrical insulation/conductivity

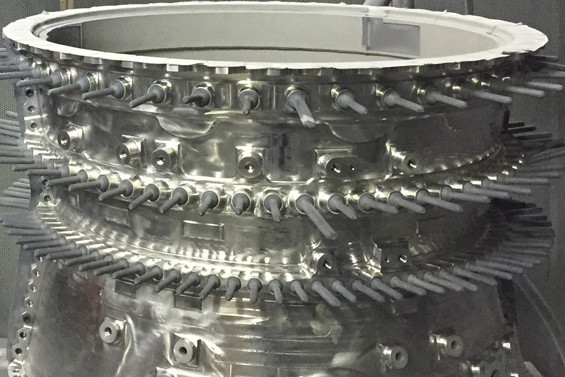

Aeronautics / Space / Defense

Recognized partners of the most demanding industries

In their search for performance, lightness, comfort and maintenance, major clients in aeronautics, space and defense collaborate with APS group companies for their recognized expertise and their high level of requirements.

Our strengths

- Our many customer qualifications in the aeronautics sector

- Our referencing as a tier 1 equipment manufacturer allows us to work on programs such as: TP400, SaM146, CFM56 and LEAP.

- Our Safran, A320-340-380 approvals for chrome baths, passivation and hardness control.

- Our ability to develop application methods and process the most complex and critical parts

Where do we operate?

Technical parts: Blades | Radomes | Fans | Engines | Platforms | Landing gear | Bindings | Filters | Sieve | Fuel lines and fluid flow (braking, clutch system, cooling) | Connectors | Electrical cable sheath | Oil tanks…

Interior parts: Sleeves | Belt buckles | Toilet bowls | Fasteners | Cabin interior decoration…

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Anti-abrasion

Repairing - Refilling

Noise reduction

Fire resistance

Wear resistance

Electrical insulation/conductivity

Atmospheric anticorrosion

Friction

Repair

Non wetting

Thermal insulation/conductivity

Surface coating for the food industry

Formulations specifically developed for the food industry

With the growth of cheaper aluminum-based equipment in the food industry, manufacturers must choose suitable coatings now. APS offers a choice of materials and coatings (fluoropolymers, silicone and Sol-gel) offering a wide spectrum of performance and meeting all your needs: coating life, hardness, food safety, etc. These properties, sometimes contradictory, require optimization of formulations and processes that APS is able to provide you. Metrasur and Lorilleux also offer on-site interventions to repair your equipment (mixers, augers, etc.) quickly while limiting line downtime.

Our strengths:

- Durability of our coatings: Some of our formulations can withstand up to 5,000 cycles per tray

- Excellence in food quality and traceability

- Energy savings by optimizing materials and designs

- Anti-stick characteristics for a reduction in the amount of fat used

- On-site interventions for repair of production equipment

Where do we operate?

Bakeware: Loaf pans | pastry or confectionery trays | cake rings…

Food Processing Equipment: Hoppers | mixing drums | agitators | mixers | cutting blades | molds and molded rolls | vibrating pans | endless screw | grids | conveyor components…

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Anti-abrasion

Food contact

Anti-stick

Repairing

Coatings for the Chemical / Water sector

A variety of processes and formulations for demanding environments

The chemical and water treatment industries have particular constraints when it comes to the choice of protective coatings and equipment repair. The APS group companies offer many suitable high-performance coatings, resistant to chemical or atmospheric corrosion, at high temperatures or guaranteeing the absence of unwanted migrations in water. Metrasur and Lorilleux also offer on-site interventions to repair wearing parts damaged by corrosion.

Our strengths:

- Chemically inert coatings to protect metal parts from harsh chemical attack up to 260°C.

- Thermal spray coatings complement the offering in case of extreme temperature conditions or mechanical constraints (cavitation, moving parts) when added to chemical attack.

- On-site repair interventions to limit production stoppages and avoid costly repurchases of new equipment.

Where do we operate?

Chemical and parachemical industry: Tanks | Containers | Vats | Reactors | Hoppers | Fans | Pump bodies | Sheaths | Piping | Filters | Valves …

Water treatment industry: Pipes and fittings (drinking and waste water treatment plants) | valves | flanges | fittings | cross connectors | bends | Y-joints …

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.