Surface treatment for the Energy / Electricity sectors

Increasingly innovative treatments for an evolving sector

In this growing sector, instruments and equipment are subjected to extreme temperatures, UV rays, pressures, corrosion and abrasion and must of course offer excellent dielectric properties.

Our strengths

- Our tier-1 referencing with demanding clients and our experience of participating in key programs in the field of energy

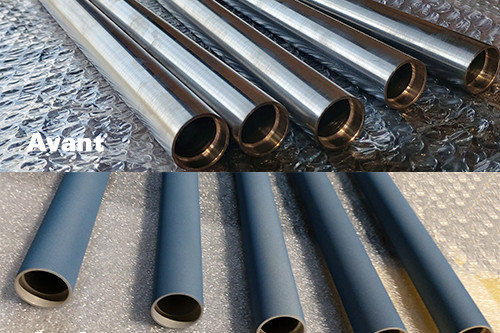

- Innovation through the development of more environmentally friendly technologies: NMP solvent-free formulations, flake zinc, repair by resurfilling of worn parts, etc.

Where do we operate?

Energy: Wind turbine blades | solar panels | tubes and pipes in electricity generation and waste incineration plants…

Electricity: Lithium Ion Batteries | connectors | wiring | underground electric cables | bindings | portable electrical equipment | light fixtures | armatures …

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Electrical insulation/conductivity

Thermal insulation/conductivity

Fire resistance

Wear resistance

Atmospheric anticorrosion

Repairing - Refilling

Friction

Noise reduction

Coatings for the Packaging market

Coatings to optimize your productivity

In this sector, reduction of maintenance times and regularity of productivity are ensured by coatings that reduce friction and make it possible to reduce energy costs.

Our strengths

- A wide choice of off-the-shelf non-stick formulations allowing immediate response to your needs

Where do we operate?

Packaging: Conveyor rails | Conveyor belts | Heat sealing bars…

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Anti-stick

Noise reduction

Wear resistance

Atmospheric anticorrosion

Repairing

Anti-friction/Slip

Surface treatment for the Printing and Textile sectors

Efficient solutions for cylinders, coils and rolls

Printing houses and textile workshops require non-stick and abrasion-resistantproperties for their cylinders in order to reduce production time and limit the cleaning and maintenance of automatic machines. Metrasur and Lorilleux also offer on-site interventions to repair printing cylinders damaged by corrosion (impacts, scratches, corrosion, etc.).

Our strengths:

- Long term experience in cylinder coatings for demanding applications (labels, etc.)

- Optimal non-stick solutions, the possibility of intervening on site and short processing times to limit your machine downtime

Where do we operate?

Printing/Paper: Drying cylinders | Lead rolls | Guide rollers | Spreading rollers | Suction roller | Spare rollers | Press rolls

Textile: Drying cylinders | Sizing Cylinders | Guide rollers | Rod | Pin bar | Soaking tanks…

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Anti-stick

Anti-abrasion

Wear resistance

Atmospheric anticorrosion

Repairing

Friction

Coatings for the healthcare sector

State-of-the-art technologies to meet the requirements of healthcare professionals

The most innovative technologies are essential to ensure optimal patient care. Coatings must be bio-compatible, offer exceptional anti-corrosion properties, excellent chemical inertness, and good shock and temperature resistance to be reliable for medical applications.

Our strengths:

- APS offers bio-compatible coatings made by thermal spraying, as well as coatings able to withstand sterilization products.

- A high quality offering recognized by high performance sectors

Where do we operate?

Instruments: Coated Medical Instruments | Trays | Pill Molds | Centrifuge Baskets | Diagnostic needles …

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.

The functionalities you are looking for

Bactericidal

Bio-compatible

Chemical resistance

Anti-stick

Friction

Coating for the Plastics and Rubber sectors

High non-stick performance for demanding cycles

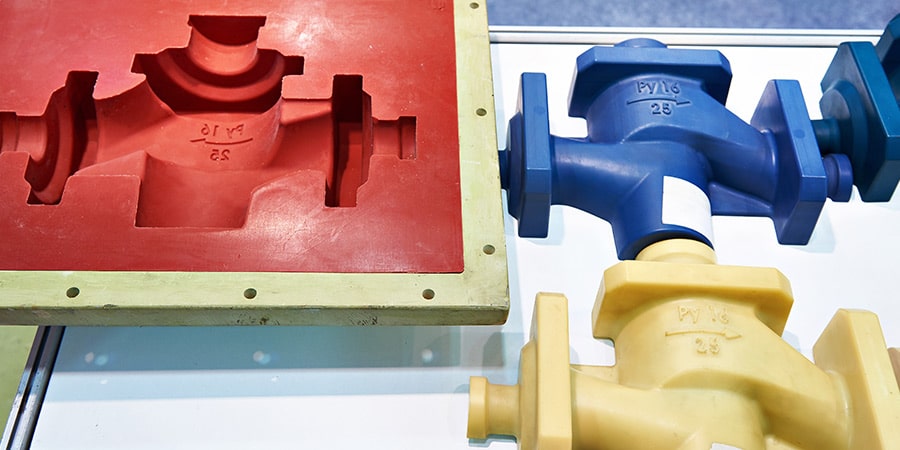

Coatings used in the plastics and rubber sector must be highly non-stick and resistant to abrasion while avoiding the use of release agents or Teflon adhesive tapes and any problem of migration of components into the material polymer or elastomer.

Our strengths:

- An expertise in the formulation of non-stick coatings to optimize the durability of moulds and facilitate de-moulding for operators

- Certifications in high performance sectors such as aeronautics and defense

- The possibility of refilling on-site molds of composite parts particularly sensitive to abrasion

Where do we operate?

Plastics / Rubber: RTM/RIM injection moulds, moulds for rotomoulding

How do we add value to your parts sustainably?

Discover through real-life projects how APS Coatings has been able to design solutions for its customers that bring real added value to their products.