Our processes

APS Coatings offers you different application processes using different production methods. Discover below in detail the diversity of APS processes.

Our expertise: dry processes

APS is recognized for the variety of its production methods and its expertise in applying the thinnest to the thickest coatings on all types of parts. With a bank of references and studies rich from 50 years of experience, our know-how covers many application processes explained below.

Polymer application

The processes in detail

- Deposited thicknesses from 2 to 80 µm

- Application temperature: between 170 and 400°C depending on the coating

- Deposited thicknesses from 80 to 300 µm

- Application temperature: between 200 and 350°C depending on the coating

- Thickness to be deposited: from 200 to 500 microns

- Application temperature: from 250 to 400°C

- Polymerization at low temperature: below 250°C

- Over 100 coatings available

- Rates of up to 2 tons of coated parts per hour

- Precisely configurable thickness: from 500 nm to 100 microns

- Application temperature: below 40°C

Metals and ceramics applications

The processes in detail

- Heat source: fuel oil (liquid) and oxygen

- Materials: metal powder and metal carbides

- Flame temperature: 2,800°C (approx.)

- Particle speed: 400 – 800 m/s

- Deposition rate: 4-12 kg/h

- Heat source: fuel oil (liquid) and oxygen

- Materials: metal powder and metal carbides

- Flame temperature: 2,800°C (approx.)

- Particle speed: 1400 m/s

- Sprayed materials: powder – ceramics, abradables, metals and their alloys

- Maximum arc temperature: 16000°C

- Particle speed: 200 – 400 m/s

- Deposition rate: 1.8-6 kg/h

- Autogenous flame at 2900°C

- Particle speed: 50m/s

- Deposition rate: 1 to 20 kg/h

- Arc voltages between 25 and 40 V

- Intensities ranging from 100 to 500 A

- Particle speed: ±150m/s

- Arc temperature: 4000°C/6000°C

- High deposit speed: 8-20kg/h

Buffer electrolysis is applicable not only in the case of industrial maintenance but also on new parts in small or medium series.

Our surface preparations

The processes in detail

Degreasing

In order to eliminate traces of grease, we can dissolve them using a solvent, transform them into water-soluble soaps or peel them off by forming a surfactant emulsion.

Sandblasting

Sandblasting makes it possible to perfectly strip, renovate, deoxidize and prepare surfaces for subsequent coatings. At APS, we have mobile sandblasting and micro-sandblasting units.

Shot blasting

We use micro-bead blasting to improve the surface appearance (similar to sandblasting) or to pre-stress to improve the technical qualities of blasted surfaces.

Phosphatation

Pickling a steel surface by phosphating provides passivation and improves the corrosion resistance of paint coatings.

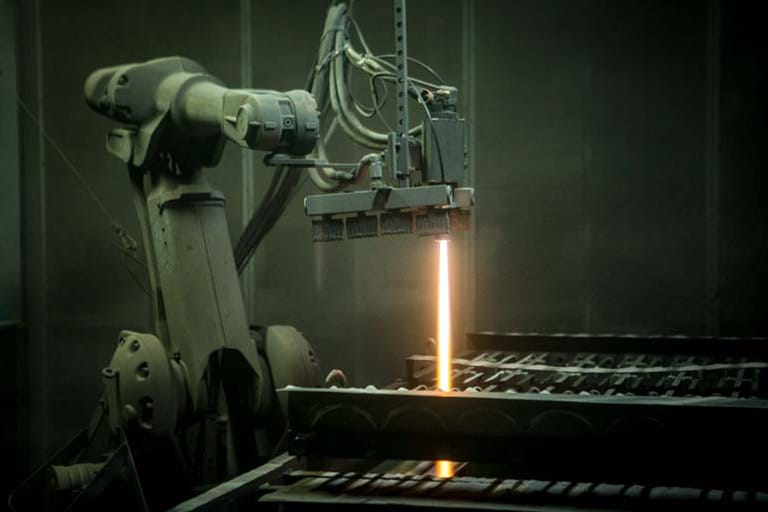

Masking

Today, we use several techniques to mask certain areas of a part: high performance adhesive tapes, metal or elastomer tools. Tomorrow, our Robocoat system will allow us to reduce or avoid this step.

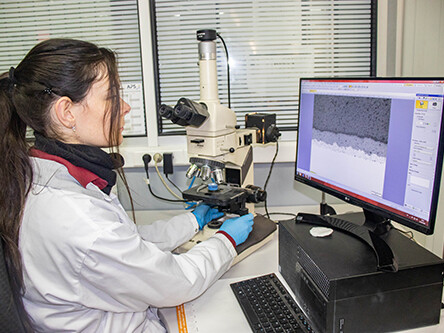

Our means of control

The processes in detail

Each workshop has an integrated quality control where the thicknesses and adhesion are measured by sampling or by unit depending on the type of parts. A visual check is also carried out systematically.

An analysis laboratory is also available to carry out destructive tests on samples in order to verify that the metallographic characteristics meet customer’s specifications.