Plasma

The plasma process is universal and differs from other thermal spray processes by its ability to apply all types of coating: metal, ceramic, polymer, carbide…

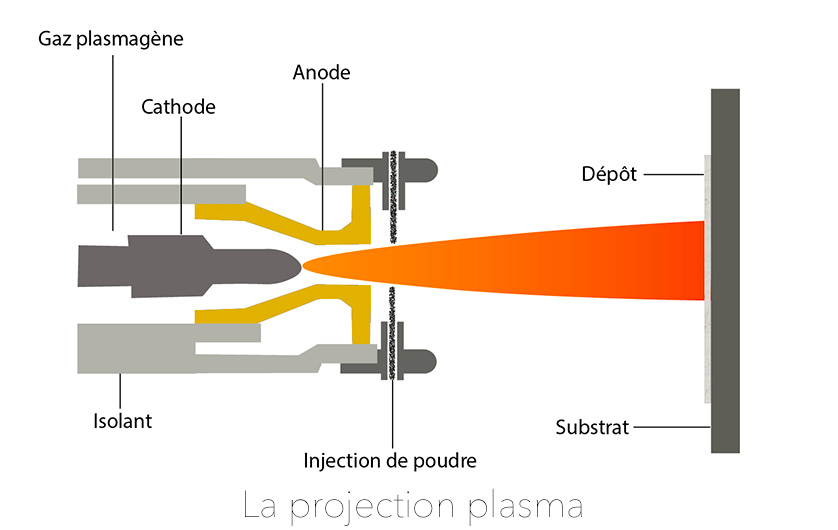

The principles of plasma spray

This technique is based on the creation of an electric arc in a mixture of plasma gas. The plasma, whose temperature can reach 16,000°C, is used to melt a stream of powder as it passes through the torch. Different “plasmagenic” gases are used such as argon, helium, nitrogen or hydrogen. The gas mixture and projection conditions can be adjusted to modify the thermal properties of the plasma as well as the particle speed. The powder flow used depends on the material to be deposited. These can be metals, metal alloys, carbides, oxides, etc. whose composition and particle size are carefully controlled. This is propelled by a carrier gas in order to be injected into the plasma gas mixture.

This technology is optimal for ceramics and abradables.

- Sprayed materials: powder – ceramics, abradables, metals and their alloys

- Maximum arc temperature: 16 000°C

- Particle speed: 200 – 400 m/s

The benefits of plasma spray

Plasma projection is carried out under atmospheric pressure and makes it possible in particular to reinforce parts intended for use in extreme conditions. The coatings obtained by this method are used in many sectors: aerospace, automotive, energy, defense, etc. It is a process:

- Ultra pure

- Suitable for all types of materials including ceramics and high melting point materials